2025台北101垂直馬拉松將於5月3日登場!台北101垂直馬拉松(Taipei 101 Run Up)是一場以台北101大樓為賽道的登高賽事,全程共91層、2046階,攀升高度達390公尺。自2005年創辦以來,便在國際馬拉松界享有盛名。

今年是南亞SAYA第三度贊助賽衣,延續去年廣受好評的全寶特瓶回收材質,結合特殊蜂巢組織與專業圖樣設計團隊打造,賽衣兼具時尚與耐穿機能,助跑者挑戰極限、再創高峰。

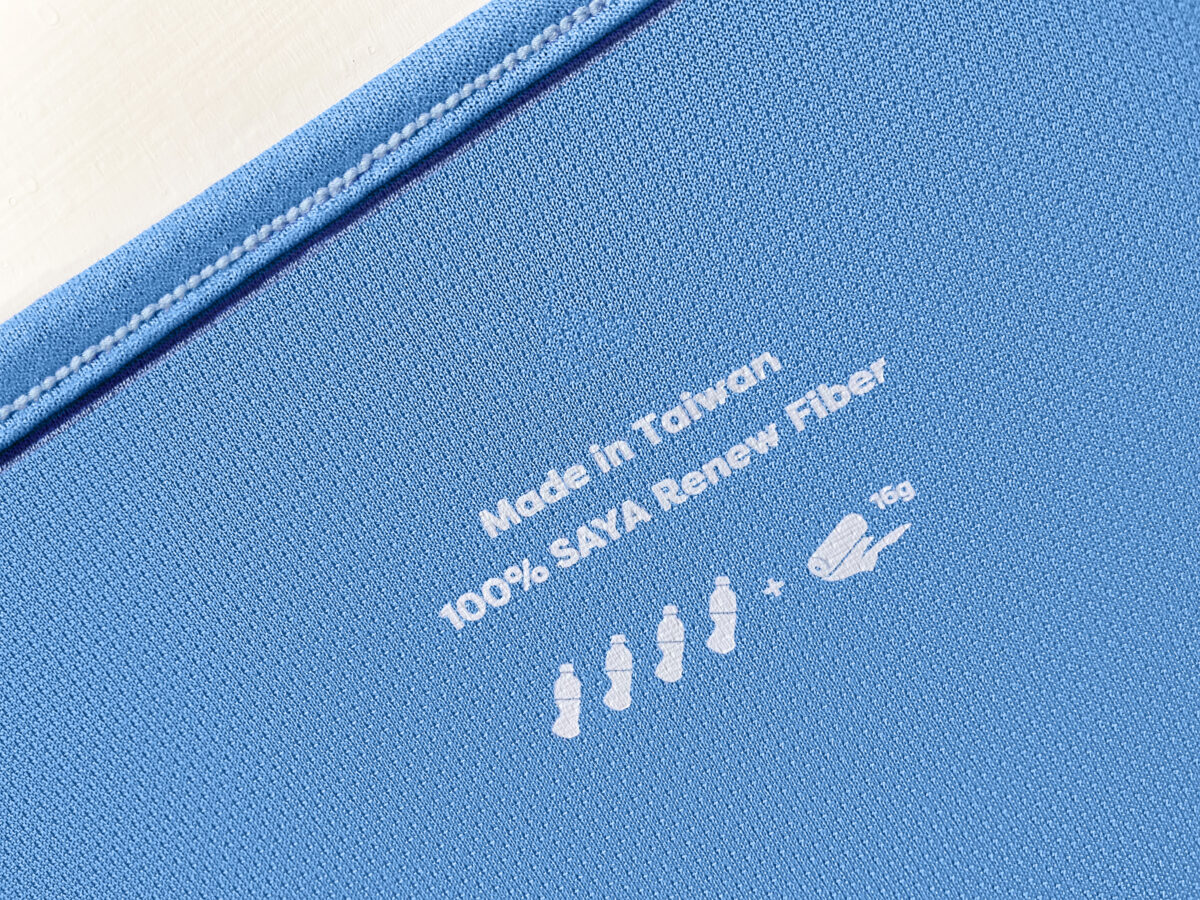

南亞SAYA於2023年也曾推出由4個寶特瓶與16克回收布料製成的零浪費異型斷面快乾纖維賽衣,兼顧循環經濟、綠色環保與穿著舒適,讓跑者全力以赴、無後顧之憂。

The 2025 Taipei 101 Run Up will take place on May 3! This iconic race challenges participants to ascend the Taipei 101 skyscraper—91 floors, 2,046 steps, and a vertical height of 390 meters. Since its inception in 2005, the event has earned a prestigious reputation in the international marathon community.

This year marks the third time SAYA, a textile renewal brand by Nan Ya Plastics, is sponsoring the race apparel. The gear continues the use of 100% recycled PET bottle fabric combined with a unique honeycomb structure and was designed in collaboration with a professional graphic design team to deliver eye-catching visuals. The result is stylish, durable performance wear that helps runners push their limits and reach new heights.

In 2023, SAYA also introduced a zero-waste race shirt made from four PET bottles and 16 grams of recycled fabric, using a special cross-section quick-dry fiber. This innovation balances circular economy principles, environmental sustainability, and wearing comfort—empowering runners to give their all, worry-free.

【蜂巢賽衣機能】

此次101垂直馬拉松賽衣採雙層布面織法織出特殊六角結構,賦予賽衣不黏身與吸水保溫的效果。

不黏身:蜂巢六角形邊框突出部分於內面,能有效減少布料在人體排汗後,潮濕衣物直接貼身所造成的不適感。

吸水保溫:吸水原理為將纖維織成有兩層結構的布面,透過內層將汗水傳導至吸水力強的外層(防止水分回流)進行蒸發,形成吸濕排汗的作用。此外,賽衣的蜂巢狀邊框於內面突起不僅可以實現不黏身的效果,同時也能降低水分蒸發時與皮膚接觸的面積,進而減少蒸發所帶走的體溫。

【Functional Features of Honeycomb Running Vest】

The running vest for the upcoming Taipei 101 Run Up utilizes a double-layer fabric weaving technique to create a unique hexagonal structure, providing the shirt with non-cling and moisture-wicking & insulation effects.

Non-cling: The protruding parts of the hexagonal frame are located on the inner surface, effectively reducing discomfort caused by fabric sticking to the body after sweating.

Moisture-wicking & insulation: The principle of moisture-wicking & insulation is associated with the double-layer structured fabric. The inner layer channels sweat to the outer layer with robust moisture-absorbing capacity (preventing water backflow) for evaporation, achieving the effect of moisture-wicking. Additionally, the honeycomb-shaped edges of the shirt, protruding on the inner surface, not only prevent the shirt from clinging to the body but also reduce the contact area with the skin during moisture evaporation, thereby minimizing the loss of body temperature caused by evaporation.

【每公斤紗線減碳1.73公斤】

此次賽衣採用SAYA 100% 聚酯(PET)回收紗線製成。

SAYA 以使用過的寶特瓶回收再製成高機能性纖維,本次賽衣使用之環保紗線相較原生紗線,每公斤可減少約1.73公斤的碳排放量。我們以環保材質得到相同機能的聚酯纖維,證明了回收材質在最終產品表現上是能與原生材質並駕齊驅的。

以可持續發展為宗旨,SAYA相信環境保護與產品機能是可以兼顧的,期待我們的堅持能夠創造更永續的未來!

【Reducing 1.73 Kilograms of Carbon Emissions per Kilogram of Yarn】

The running vest for this event is made from SAYA 100% recycled polyester (PET) yarn. SAYA utilizes recycled PET bottles to produce high-performance fibers. Compared to virgin yarn, the environmentally friendly yarn used in this running vest can reduce approximately 1.73 kilograms of carbon emissions per kilogram. We have proved that recycled products are just as good as virgin products by achieving the same functionality with environmentally friendly materials.

With a commitment to sustainability, SAYA believes that environmental protection and product functionality can go hand in hand. We hope that our dedication will contribute to creating a more sustainable future!

2024台北101垂直馬拉松將於五月舉行!台北101垂直馬拉松(Taipei 101 Run Up)是一場以台北101大樓作為比賽場地的登高賽,91層樓、2046階、高度390公尺的獨特形式馬拉松,自2005年開辦以來就在國際馬拉松界享負盛名。本次賽事被國際登高協會(Towerrunning World Association)列為世界冠軍賽(World Championships 2024),預計將吸引許多國際好手前來共襄盛舉。

2024台北101垂直馬拉松將於五月舉行!台北101垂直馬拉松(Taipei 101 Run Up)是一場以台北101大樓作為比賽場地的登高賽,91層樓、2046階、高度390公尺的獨特形式馬拉松,自2005年開辦以來就在國際馬拉松界享負盛名。本次賽事被國際登高協會(Towerrunning World Association)列為世界冠軍賽(World Championships 2024),預計將吸引許多國際好手前來共襄盛舉。