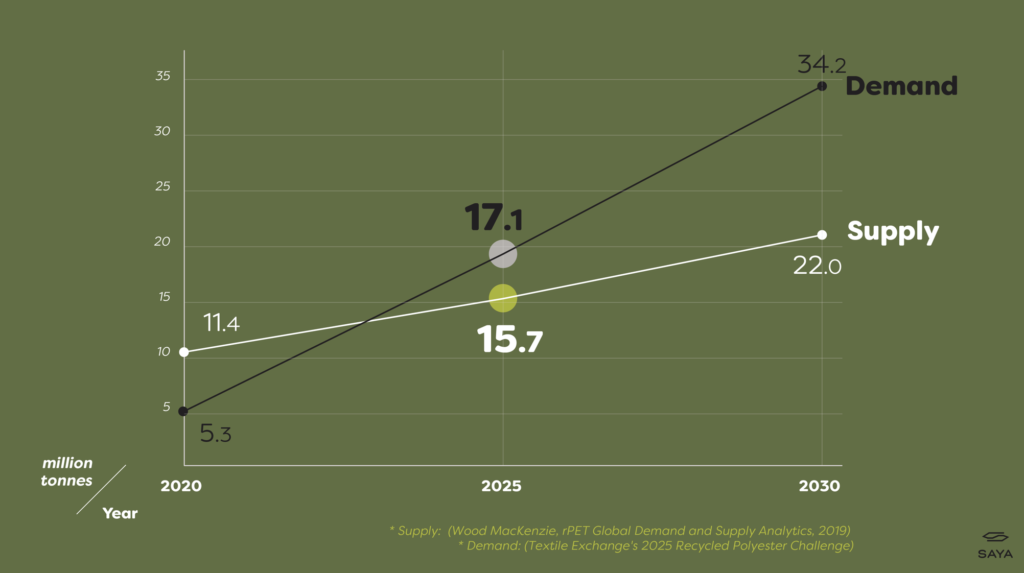

As consumers’ appetite for recycled polyester products grows, the industry is facing an unintended consequence: There may not be enough recycled plastic bottles available to meet the demand.

Campaigns such as the Recycled Polyester Challenge 2025 inspired brands to move away from virgin polyester and use recycled fibers. The challenge is to increase recycled polyester usage from the current 14 percent to 45 percent by 2025. As a result, Textile Exchange estimates we’ll need 17.1 million metric tonnes of recycled polyester to cover apparel industry demands.

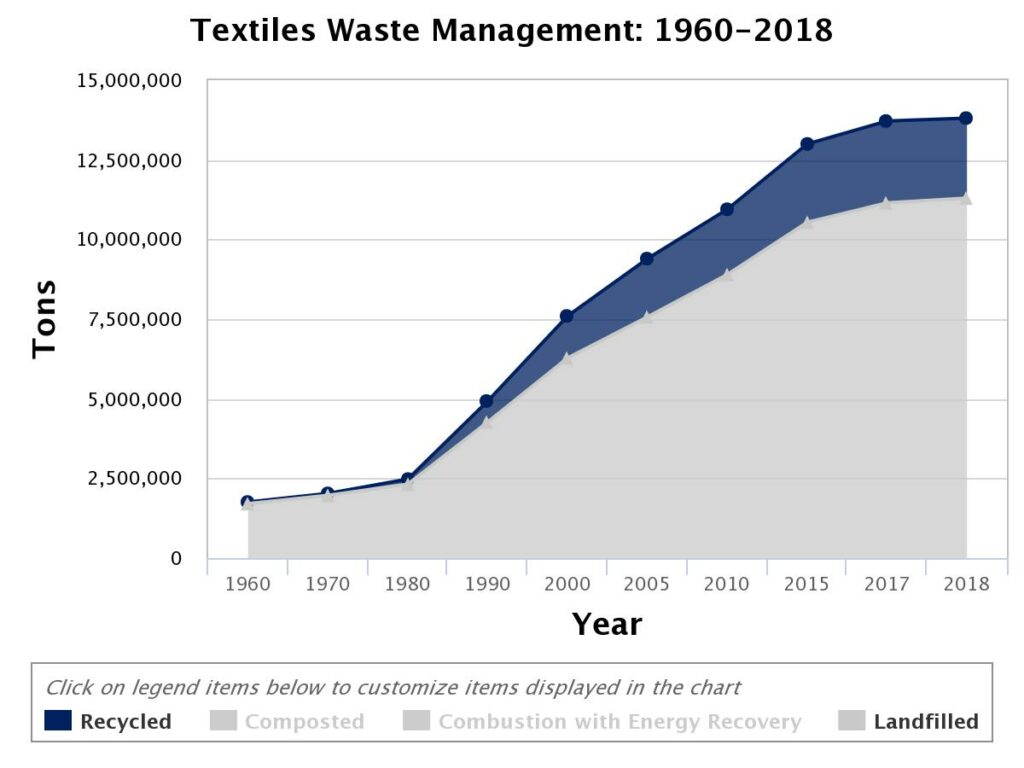

In 2017, roughly 47 percent of all available recycled PET in the United States went to fiber products, according to the Association of Plastic Recyclers (APR) and NAPCOR’s “Report on Postconsumer PET Container Recycling Activity in 2017.” Food and beverage companies were the second largest users of rPET, at 21 percent.

Meanwhile, the volume of PET bottles available for recycling in the U.S. declined for the first time since 2009. As Wood Mackenzie reports, most of the world’s bottle collection volume comes from a few key markets (in Western Europe and Asia, primarily), and collection rates are not rising enough to keep pace with demand.

If this trend continues, there simply won’t be enough bottles in recycling bins to cover the need for rPET.

But, we can help change that. Here are some important ways consumers and businesses can help meet the demand.

Raising Awareness About Recycled Plastic Bottles

Of course, we don’t want to resurrect virgin bottle usage. However, we can raise awareness to increase recycled plastic collection percentages, especially in the U.S. The problem is not a lack of bottles to recycle. It’s that not enough consumers are recycling.

The U.S. falls behind on recycling compared to other nations, while being the biggest consumer of them all. Add to that: The current recycling infrastructure and state policies governing recycling influence the amount of PET that enters the pipeline. Outdated technology in some states and municipalities, plus lack of public education means that consumers don’t know what kinds of plastics can be recycled. Or, they try to recycle contaminated plastic, which is rejected by older systems.

The countries that lead the world in recycling, such as Germany and Taiwan, have robust nationwide support for recycling programs, government recycling goals, public awareness campaigns, incentive programs, and strict recycling policies for producers.

If you want to see an increase in recycling rates near you, talk with your city or county officials or neighborhood association. Find out what’s stopping the flow of bottles to recycling centers. See if there are ways to lower those barriers or incentivize people to recycle more.

Businesses As Influencers

A few things are happening on the corporate level that are influencing the supply of recycled plastic, for better or worse. First, many large corporations and travel companies have pledged to eliminate all single-use plastic. This is great news for the environment, but has an impact on rPET supply. Our hope is that they will continue to offer recycling for customers who bring plastic to their properties.

Second, big beverage brands like PepsiCo and Coca-Cola are switching to rPET and asking customers to return empty plastic bottles to be remade into new bottles. In the U.S., the goal is that all Pepsi-branded products will be converted to 100 percent rPET bottles by 2030. Meanwhile, Coca-Cola has been rolling out bottles made from 100 percent recycled PET in North America since early 2021. To influence their customers to recycle, the beverage brands are offering bottle recovery programs. This ensures that they have a steady stream of PET to recycle into new bottles.

What if more apparel companies and fiber brands offered bottle or fiber recovery programs too? Allowing customers to send in post-consumer PET or donate it at the point of purchase could help the supply problem. Brands could incentivize customers by offering them a discount on new products when they recycle their old plastic and polyester. Some brands are already doing this with success.

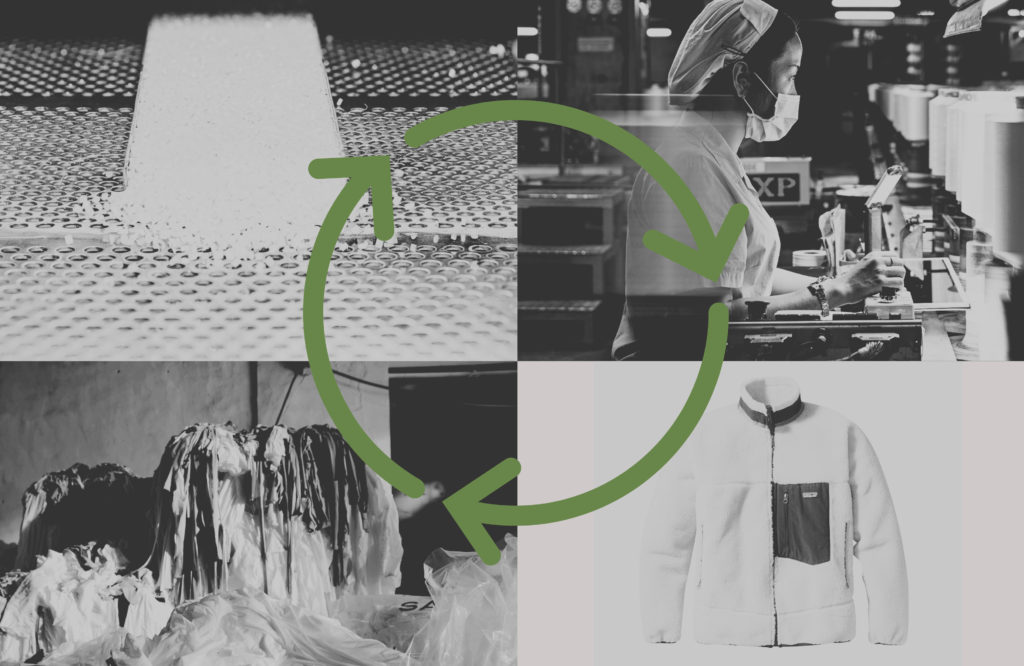

By expanding this and creating a reliable pipeline, we could make the polyester industry more circular, capture bottles and fabrics before they make it to the landfill, and keep the supply flowing strong. To learn more about how you can join us, contact change@sayarenew.com