It is nearly impossible to imagine a world without polyester. Polyester or recycled polyester is used to make synthetic fabrics, industrial fibers, yarns, and ropes used in everything from car tire reinforcements to conveyer belts. It is in cushions and quilts, upholstery, and more. Given how essential polyester is in modern life, it is hard to believe it is less than one hundred years old.

What is Recycled Polyester and Why Should We Use It?

Since its widespread adoption for myriad uses, polyester has revolutionized how we build, insulate, protect, and transport materials. It’s a mighty material whose evolution from an accidental discovery in a laboratory to a galvanizing force for innovative, large scale recycling. So, what, exactly, is it?

History of Polyester

Polyester was discovered by scientist W.H. Carothers in a DuPont lab in 1926. Carothers discovered that alcohols and carboxyl acids could be mixed to create synthetic fibers, but his work on polyester was shelved so that he could focus on nylon. A decade later, British scientists John Winfield and James Dickson continued Carothers’s work, and by 1941, the two patented polyethylene terephthalate (PET). Polyester was officially born. By 1950, DuPont, an American company, had acquired all the legal rights to polyester, producing the fiber Dacron, followed soon after by Mylar. In the 1950s, polyester was marketed as a miracle fabric: it was durable and did not wrinkle. For about two decades, polyester enjoyed widespread popularity. However, by the 1970s, polyester fabrics had developed a reputation for being uncomfortable and potentially harmful to the environment. Since then, manufacturers have improved polyester yarns used in clothing to improve comfort. More, polyester fibers remain widely popular and used in a vast range of applications. And major advances in the technology to recycle polyester have made the material’s production more sustainable.

How Polyester is Made

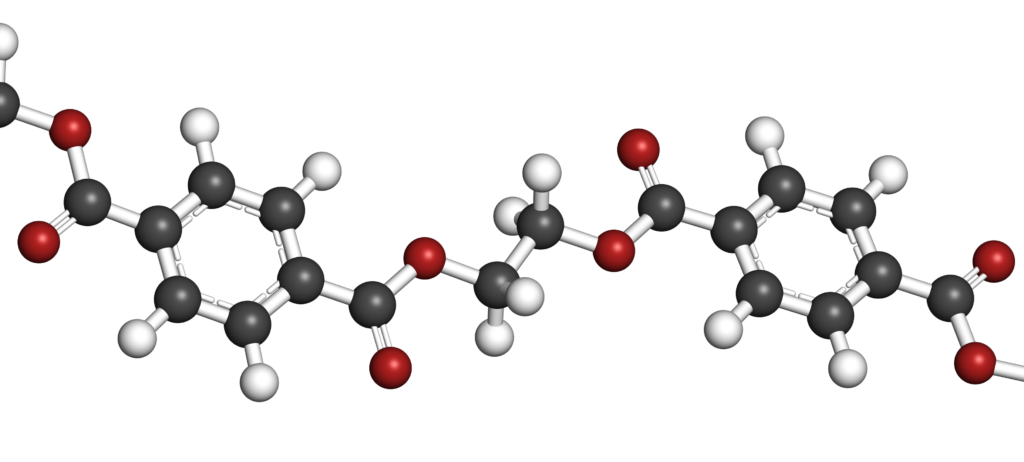

Polyester (polyethylene terephthalate, or PET) is a man-made fiber derived from petroleum, air, and water. Essentially a plastic, polyester is made by mixing ethylene glycol and terephthalic acid. Polyester fibers are formed through a chemical reaction where two or more molecules combine to make a large molecule whose structure repeats throughout its length. Polyester fibers can form very long, stable, and strong molecules.

Common Uses for Polyester

It is easier to say what polyester is not used for than what it is. That’s because polyester can be found in almost every element of modern life. Some of polyester’s most common uses include:

Recycled Polyester

Demand for recycled polyethylene terephthalate (PET), or polyester, has increased significantly in recent years. There are many advantages to recycled polyester, including reduced energy consumption in the manufacturing process as compared to producing virgin polyester; reduced CO3 emissions, and reduced extraction of crude oil and natural gas to make virgin plastic. There are two techniques for producing recycled polyester: mechanical recycling and chemical recycling.

Opportunities for Polyester

SAYA is dedicated to innovating polyester recycling technology to reduce waste, drastically decrease the use of fossil fuels in polyester production, and to create a more sustainable approach to manufacturing polyester. Because polyester is an essential fiber used throughout modern society, leveraging opportunities to recycle polyester is paramount. A sampling of SAYA innovations include:

· Advanced bottle recycling, which produces recycled bottle fiber for a range of uses.

- Fashion

- Sportswear

- Fleeces

- Coats and parkas

- Bedding such as sheets, comforters, and sleeping bags

- Footwear

- Fillings for comforters (due to its insulating properties)

- Sewing threads

- Soft furnishings and upholstery

- Textiles

- Luggage and other bags

- Industrial polyester fibers are also used in conveyor belt fabrics, seat belts, plastic reinforcements, and more.

- Plastic bottles and containers for food and liquids

· Rscuw Next, which provides a renewal solution for offcuts and rolls of fabric that don’t make it into the garment.

· SAYA Garma, a complex recycling process of pre and post-consumer garments that will streamline garment recycling by offering turnkey retail to fiber solutions. Estimated availability: late 2021.

In its relatively short life, polyester has undergone several important iterations. This strong, durable, and enduring fiber has gone from creating leisure suits to ubiquity. As we look to the polyester of the future, recycling and other innovations will play an important role.

To share your thoughts on recycled polyester or to learn more about SAYA fiber, please contact us at change@sayarenew.com